ITF Servicees

Request access and start quotes for service using iLabs

Transgenic Insect Production ITF is a “state of the art facility” for the production of transgenic insects. Microinjection service includes preparation of “injection quality” DNA, verification of DNA based on client supplied DNA, Injection mix preparation (Injection Mix includes clients vector, transposase source, and ITF-QA plasmid), an “effort” of microinjection into pre-blastoderm embryos (see below for species specific “effort” definitions), Backcrossing of G0 individuals to “non-injected individuals, progeny of these crosses will be screened for transformation markers (i.e. fluorescent proteins, eye color mutant or other phenotype). Putative transformants will be confirmed by Transposable Element (TE) Display. Transgenic individuals will be shipped to the client (typically at G3).

Species Specific Microinjection “effort”

- Aedes aegypti: 75 G0 adults

- Anopheles stephensi: 75 G0

- Anopheles gambiae: 150 G0

Insect Transformation Protocol Development ITF personnel can develop custom injection protocols for insect species that have not been previously transformed. Protocol development includes, determination of embryo injection timing, pre-injection treatment (Chorion removal, Desiccation, Enzymatic softening), appropriate needles, and suitable vector system. ITF can work with clients on Injection protocol development as subcontractor, collaborator or in a fee for service capacity.

Back-up rearing After transgenic lines are sent to the client, ITF can, at an additional charge, rear lines for the client as a back up during establishment of colonies in the client’s laboratory. This service is limited to 4 generations post shipment and will not be extended beyond this termination point.

RNAi Microinjection ITF will inject client’s dsRNA for RNAi knockout. DsRNA can be injected into embryos, larvae, or adults based on the clients need. Fees are charged on a per hour basis with a 2 hour minimum and at least 200 embryos injected.

Engineered RNAi Microinjection of plasmid vectors engineered to transcribe DsRNA as extended hairpin-loop RNA for gene knock out. Service is the same as outlined for Insect Transformation Injections.

Consultation

- Plasmid vector construction ITF personnel can help with the design of your Transformation vector. They can give helpful information on promotors, markers and other structural components.

- Embryo microinjection. We have experience with a wide variety of insects, including Diptera, Coleoptera, and Lepidoptera.

- Grant Consultation.

- Needle fabrication Our staff has 10 years of experience in needle fabrication and is willing to discuss what works for us or how you may improve your needles.

- Microinjection facility set up If you are setting up your lab for insect microinjection, please schedule a visit to our facility to see and test our equipment.

- Mosquito Transformation Experienced in all aspects of mosquito transformation, from injection, rearing, screening, and confirmation.

- Fruit Fly Transformation ITF personnel have experience in Transformation of Exotic Fruit Flies and can be of assistance; however USDA regulations on the importation of Exotic Fruit Flies do not allow us to work on Exotic Fruit Flies in our facility.

- New Insect Transformation Protocols If you would like to produce transformant insects for a species that does not currently have a protocol, ITF personnel can help with the development of new protocols.

Training If you are interested in learning any of the techniques associated with Insect Transformation ITF can provide training. Training can be set up for individuals, laboratories or groups. Areas of training include a) Needle Fabrication, b) Microinjection c) RNAi injection, d) Vector construction, e) Transposition assays, and f) Insertion Confirmation. The ITF is in the process of developing an Insect Transgenesis workshop.

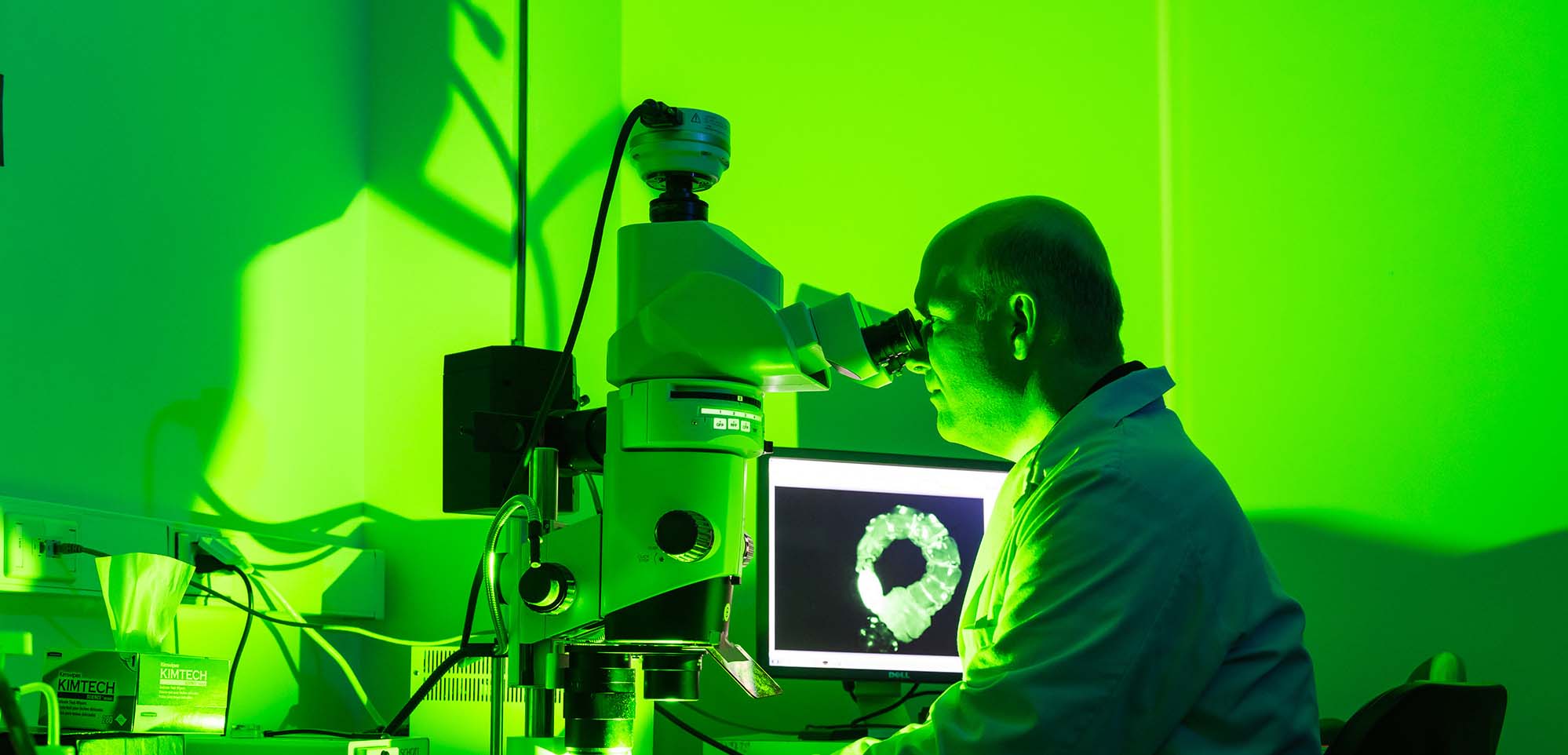

Facility Use If you would like to perform your own microinjections, you can lease time in the ITF. The facility consists of 2500 square feet of laboratory space with a biochemistry laboratory, insectary, vivarium, and a “state of the art” microinjection suite. The microinjection suite is equipped with 3 microinjection stations designed to accommodate 2 person injection teams. These injection stations are based on dissecting microscopes making them ideally suited for insect embryo microinjection enabling ITF clients to perform insect transformation and RNAi injection. A microinjection needle fabrication area is also located within the microinjection suite with a P-2000 laser micropipette puller, 2 micro-needle bevelers, and a microforge for creation of glass micro-tools. Leasing time in ITF allows clients to use our equipment and space, in addition to having ITF personnel available for help.